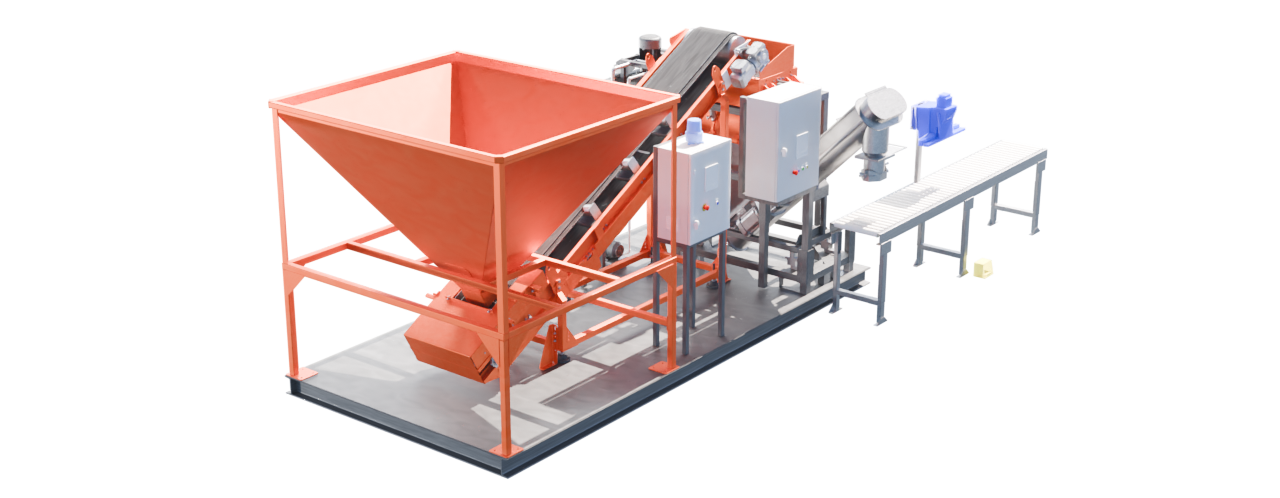

Asphalt mixing plant

Specifically developed to bring agility to construction industry professionals, the Emix is the compact version of the industrial asphalt mixing units well known in the sector.

With a capacity of 2 tons per hour and full automation, it is a versatile machine, suitable for both occasional batches and regular production. Focused on the production of storable asphalt mix, Emix is the perfect companion to VIALAB emulsion production units, allowing immediate application of fluxed emulsions and seamless packaging of the mixture.

Français

Français Español

Español