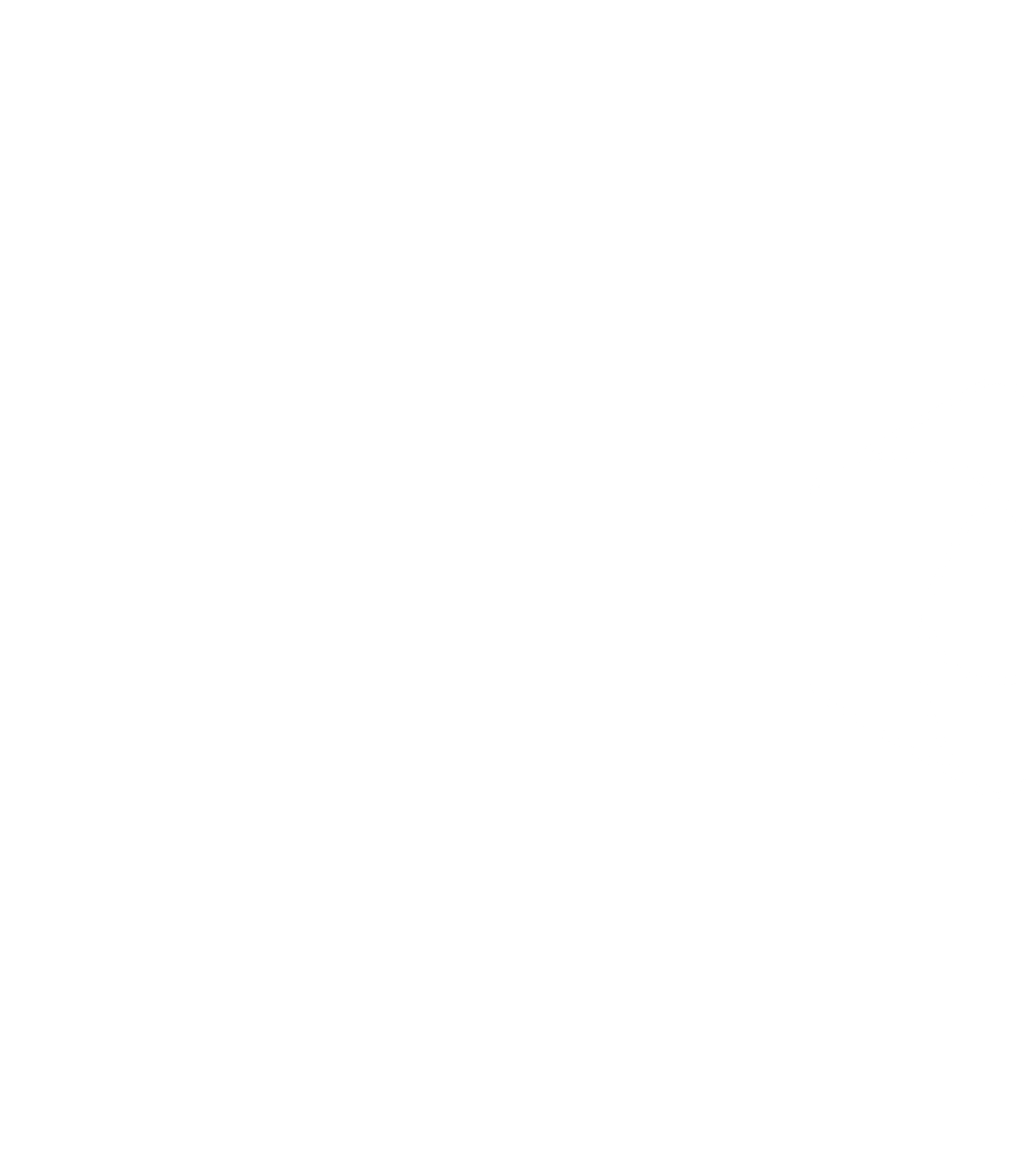

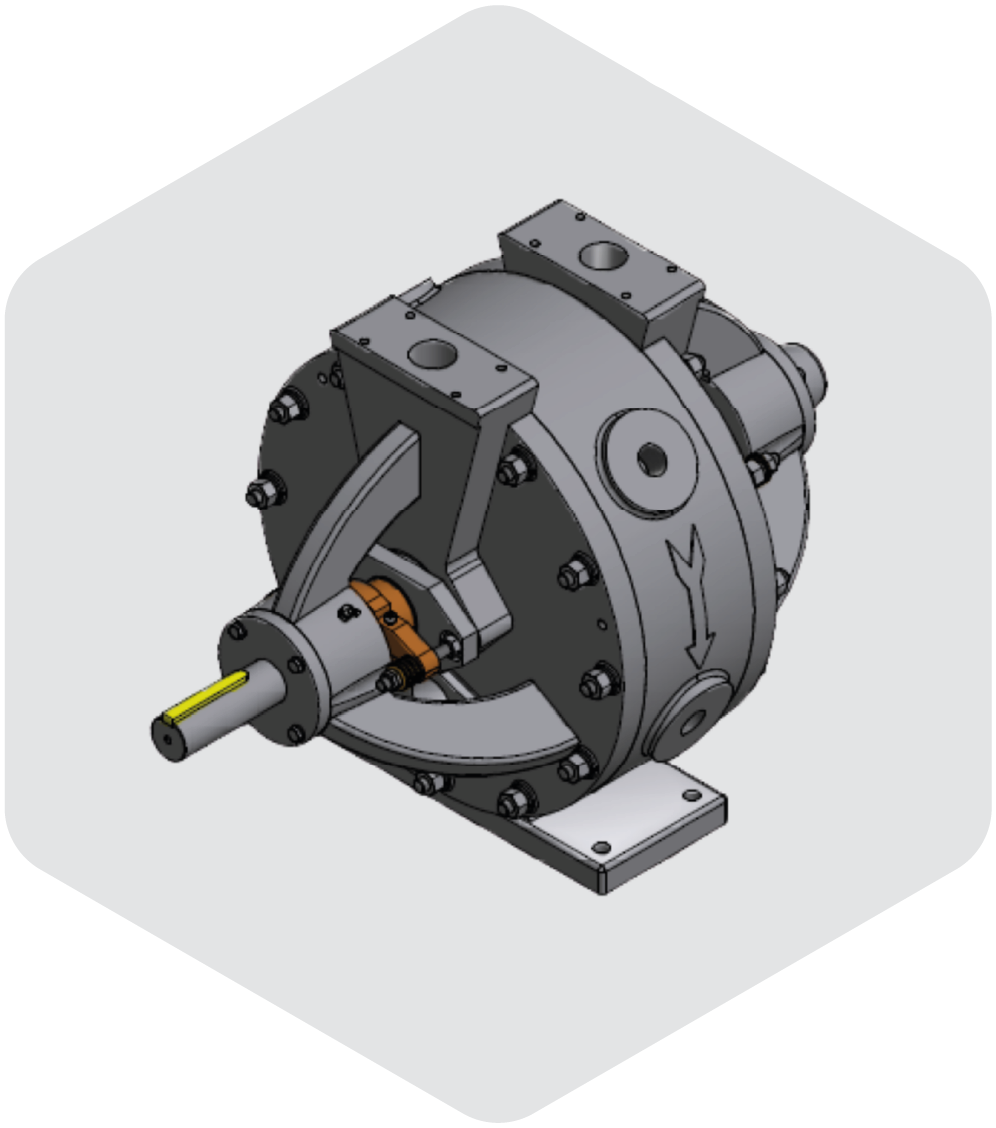

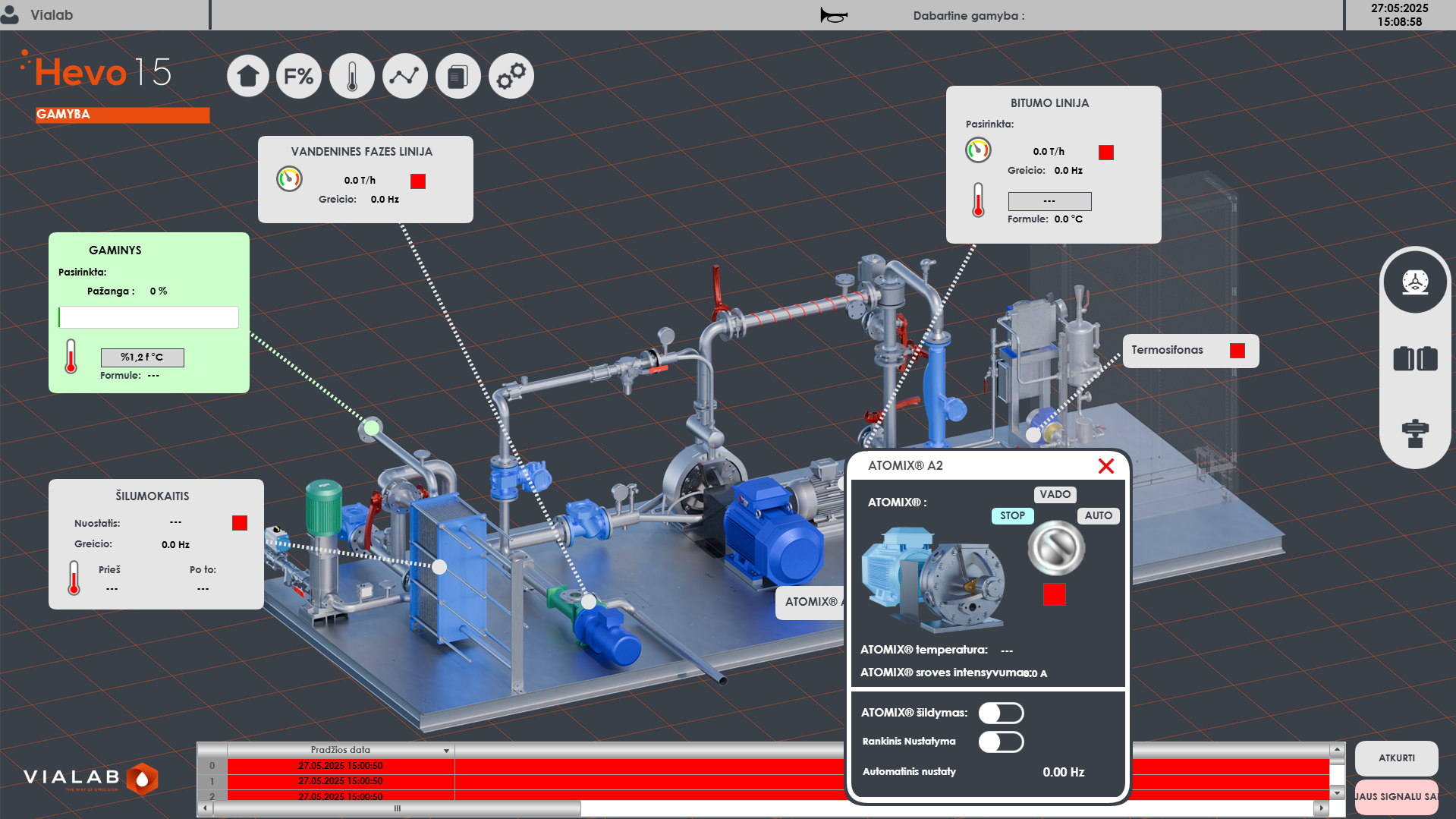

Colloid mill ATOMIX®

Patented in 1933, ATOMIX® technology is an integral part of all our bitumen emulsion production units as well as our laboratory pilots.

ATOMIX® homogenizers, also known as colloid mills, are used across various industries for the production of dispersions.

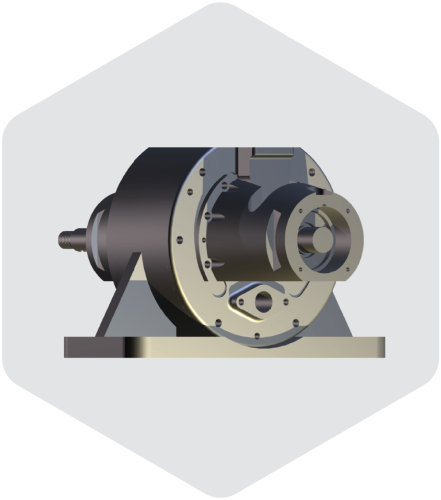

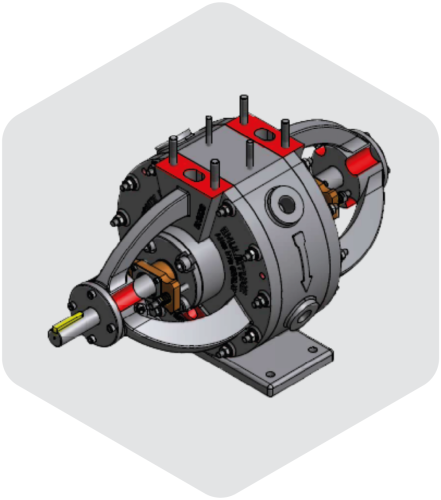

The compounds to be emulsified are injected into both ATOMIX® inlets toward the rotor’s curved blades. They are then propelled against the stator walls, causing the fluids to break into fine droplets and enabling the production of high-quality emulsions.

Français

Français Español

Español