Products

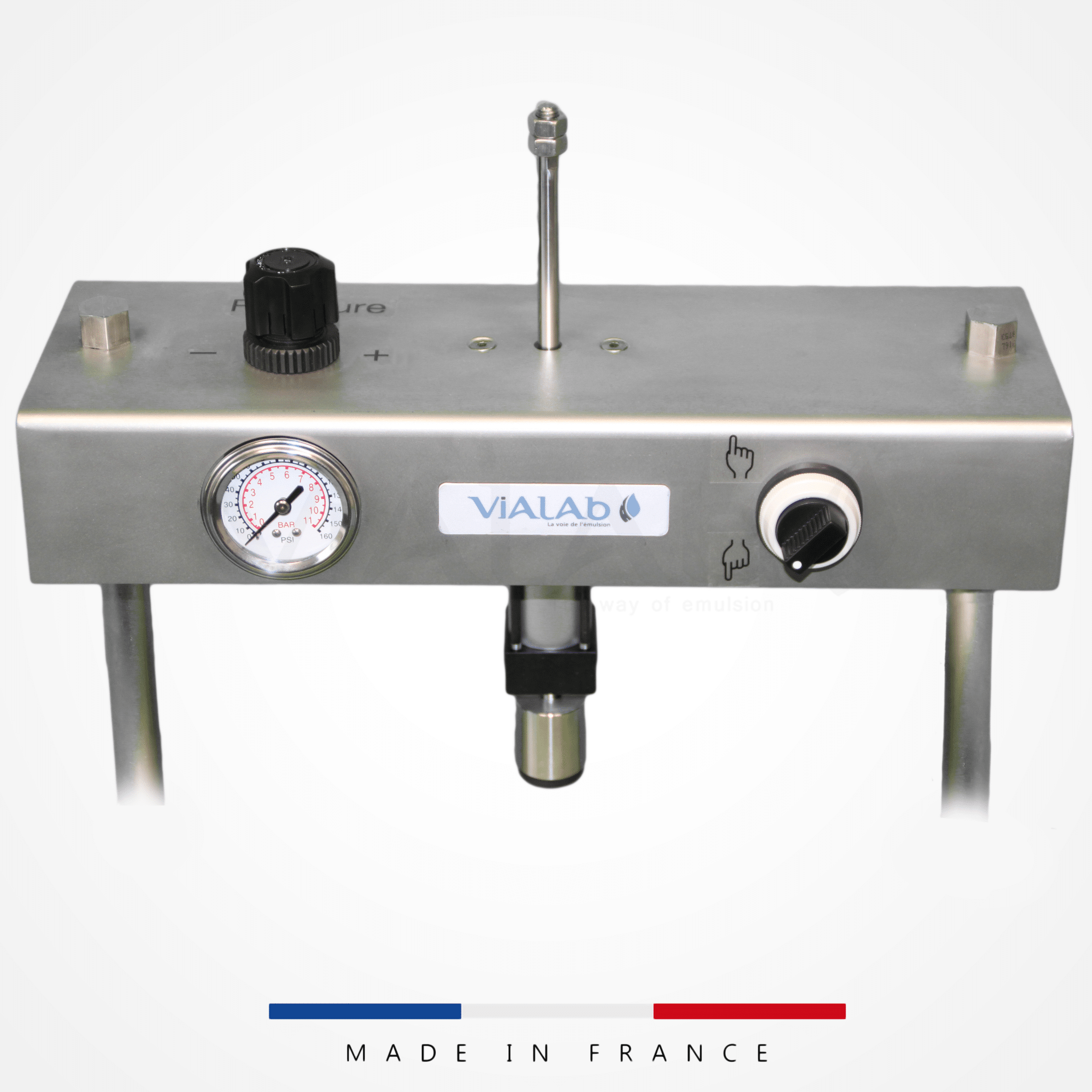

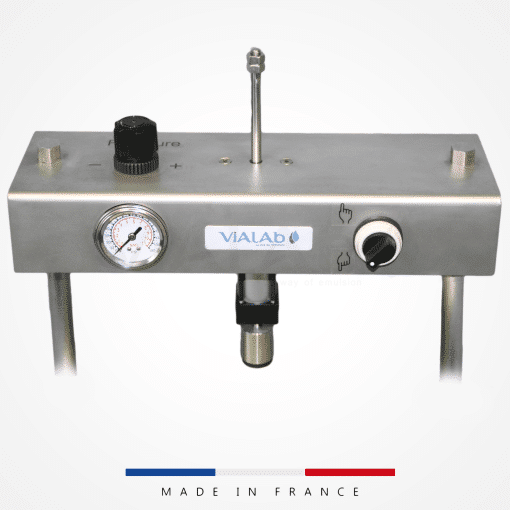

COHESION tester - Complete set EN 12274-4

Complete set for determining the Cohesion of Slurry- and Microsurfacing

Specifications:

– Cylinder double effect with double rod, piston diam. 8mm with stroke 76mm

– Mechanical distributor 5/2, two positions with manual control

– Air pressure regulator with manometer 0-800 KPa

– 35 kg/cm torque wrench,

– Grit calibration paper P100 and P220

– Calibration sand

– 10 Sheets of 100×100 mm felt,

– Spare foot and Air hose jack.

– Molds type A, B, C and D to be ordered separately.

F044.153.0010

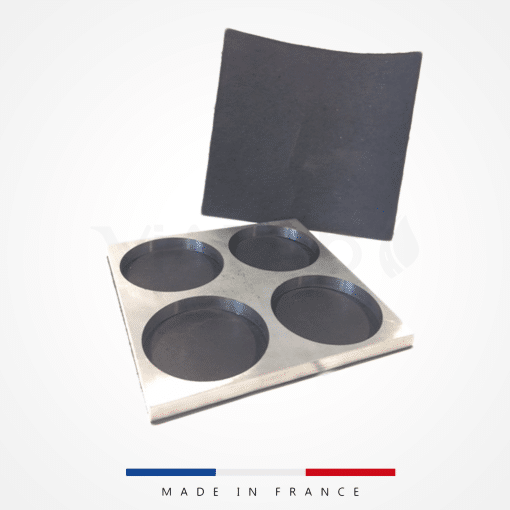

Mold Type A (EN)

- 4 positions

- Size 140×140 mm

- Depth 6.3 mm

- Ø. Sup. 60

- Ø. Inf. 60.3 mm

F044.153.0012

Mold Type B (EN)

- 4 positions

- 140×140 mm

- Depth 10 mm

- Ø. Sup. 60

- Ø. Inf. 60.4 mm

F044.153.0020

Mold Type C (EN)

- 4 positions

- 200×200 mm

- Depth 13 mm

- Ø. Sup. 90

- Ø. Inf. 90.6 mm

F044.153.0021

COHESION Tester - Complete set for ASTM D3910 / ISSA TB139

Complete set for determining the Cohesion of Slurry- and Microsurfacing according to ASTM D3910 and ISSA TB139

Specifications: ASTM D3910 – ISSA TB-139

– Cylinder double effect with double rod, piston diam. 8mm with stroke 76mm

– Mechanical distributor 5/2, two positions with manual control

– AIr pressure regulator with manometer 0-800 KPa

– 35 kg/cm torque wrench,

– Grit calibration paper P100 (x5) and P220 (x5)

– Calibration sand

– 10 Sheets of 100×100 mm felt,

– In option, Laboratory compressor Metabo 8 bar

F044.153.0011

Set of 10 Stainless Steel molds ASTM D3910 - ISSA TB-139

- 10 molds Ø70 mm, depth 6 mm (x5) and depth 10 mm (x5)

F044.153.0013

ACCESSORIES

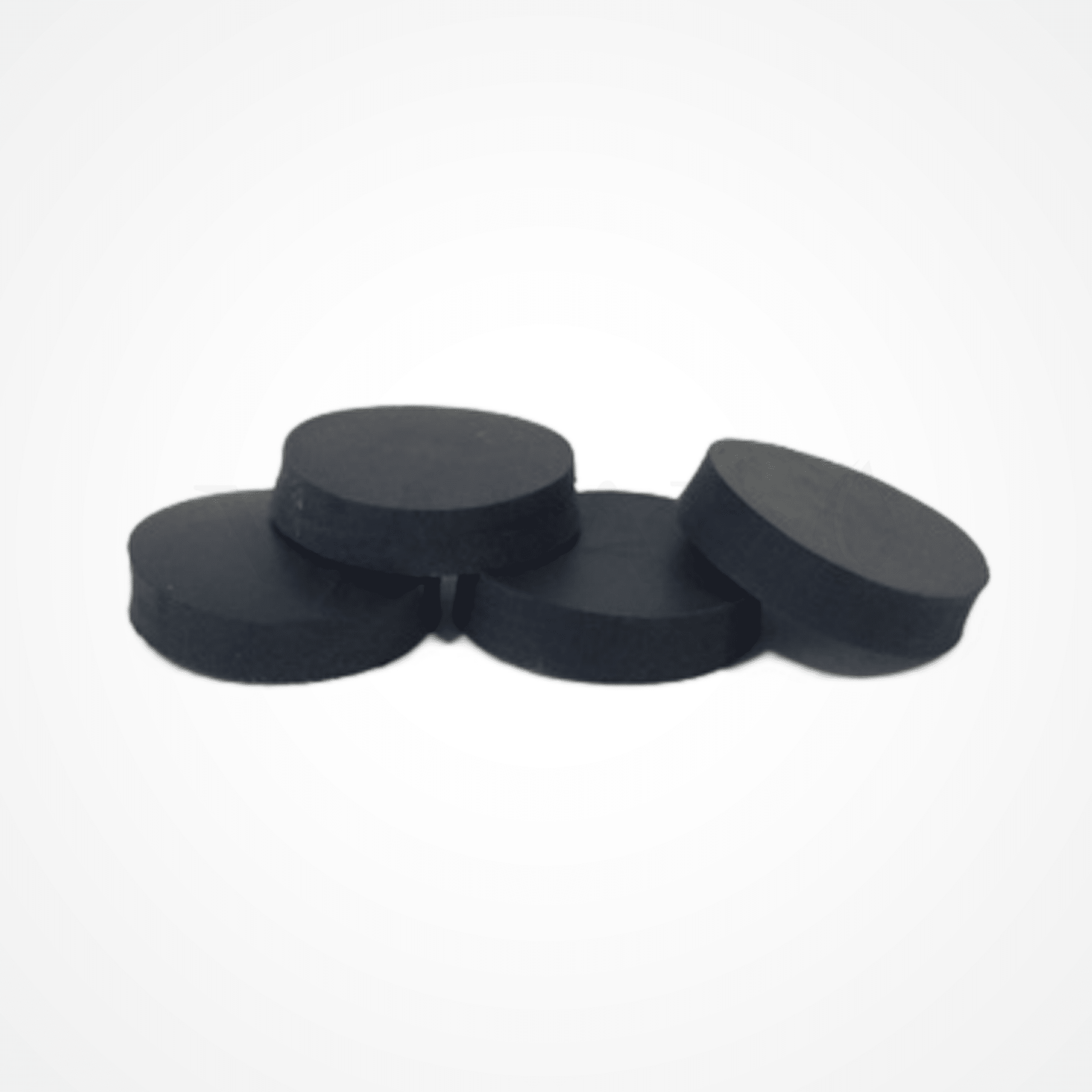

Set of 10 neopren footpads 25.4 mm - ASTM D3910 / ISSA TB 139

Specification

- ASTM D3910 ; ISSA TB139

- ∅ 25.4 mm

- Thickness: 6.3 mm

- Shore hardness 60 ± 5

F044.153.0016ASTM

Set of 10 neopren footpads 28.5 mm - EN 12274-4

Specification

- EN 12274-4

- ∅ 28.5 mm

- Thickness: 6.3 mm

- Shore hardness 60 ± 5

F044.153.0016EN

10 sheets Roofing felt (700 ± 70 g/m²) - 100x100 mm - ASTM / ISSA

Specification

- EN 12274-4

- ∅ 28.5 mm

- Thickness: 6.3 mm

- Shore hardness 60 ± 5

F044.153.0014ASTM

10 sheets Roofing felt (700 ± 70 g/m²) - 140x140 mm - EN 12274-4

Specification

- EN 12274-4

- ∅ 28.5 mm

- Thickness: 6.3 mm

- Shore hardness 60 ± 5

F044.153.0014EN

AIR COMPRESSOR 50L, 8 bars, 230 V mono

Specification

- Capacity: 50 liters

- Engine: 1.5 kW (2 Hp) at 2850 rpm – 14 m³/h

- Pressure: 8 bars

- Alimentation: 230 V mono

- Dimensions: 830 x 380 x 720 mm

- Weight: 36 kg

F081.107.0701

Français

Français Español

Español