Products

Made in France – Exclusivity VIALAB

Specifications

Mechanical

- 316L Stainless steel heat-insulated bath with a useful length of 1500 mm

- Robust pulling trolley in microblasted stainless steel 10 mm thick

- Adjustable carriage speed from 0 to 1500 mm / min

- Displacement accuracy 0.001 mm

- High precision mechanical guidance system 5 mm / Ø rotation

- Machined trapezoidal ball screw

- Traction system and distribution of forces in 3 points

- Ball shuttles with self-lubricated bearings on treated hard steel rails

- 4 Traction lines with stainless steel positioning paddles

- Robust welded square tube frame with anti-rust finish paint

- 4 height adjustable feet

- Perforated protective grid in the bottom of the bath

- Lever-operated 1/4 turn drain valve

Control electronics & power

- High Performance Brushless Servo Motor with ServoDrive variable speed drive

- 23 Bit absolute position encoder (8,388,608 positions over 1500 mm)

- Capacitive limit switch safety sensors at the ends of the bath

- Latest generation programmable logic controller with Ethernet connection interface

- Control via PC in direct connection or via LAN network (remote control possible)

- High acquisition frequency

- Automatic detection of breakage (if load cells installed)

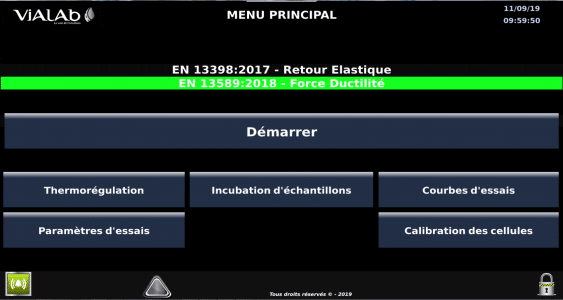

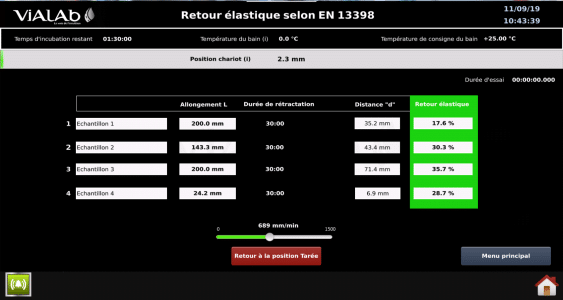

- Determination of elastic return with automatic calculation function

- Emergency stop on the front

- Power on indicator light

- Power switch-disconnector

- Management of sample incubation

- Taking Remote Control

- Power supply: 230 VAC, 50Hz, 750W

Thermodynamics

- Circulating thermostat for temperature regulation from 5°C to 60°C at ± 0.5°C (chiller required for temperatures below or equal to ambient temperature down to -20°C depending on model)

- Control head with 2000 W heating coil

- Water level detection diver

- Pressure pump integrated in the control head

- Homogeneous distribution of the liquid flow in the bath thanks to the diffuser tube

Dimensions

- Dimensions (LxWxH; mm): 2360x580x310

- Weight: 140 kg

Accessories

- Windows laptop PC configured at the factory for controlling the ductilimeter

- Basic cooler for temperatures of + 5°C at room temperature (4 hours to reach 5°C at a temperature of 20°C)

- Performance cooler for low temperatures (down to -20°C) and for faster temperature drop

- 300 / 0.1 N Load cells and signal conditioners

Evolution to EN 13589 ductility force test by adding force cells and signal conditioners

- 100% French manufacturing

- CE Certificate

F044.136.1500

Specifications

Mechanical

- 316L stainless steel heat-insulated bath with a useful length of 1500 mm

- Robust pulling trolley in microblasted stainless steel 10 mm thick

- Adjustable carriage speed from 0 to 1500 mm / min

- Displacement accuracy 0.001 mm

- High precision mechanical guidance system 5 mm / Ø rotation

- Machined trapezoidal ball screw

- Traction system and distribution of forces in 3 points

- Ball shuttles with self-lubricated bearings on treated hard steel rails

- 4 Traction lines with stainless steel positioning paddles

- Robust welded square tube frame with anti-rust finish paint

- 4 height adjustable feet

- Perforated protective grid in the bottom of the bath

- Lever-operated 1/4 turn drain valve

Control electronics & power

- High Performance Brushless Servo Motor with ServoDrive variable speed drive

- 23 Bit absolute position encoder (8,388,608 positions over 1500 mm)

- Capacitive limit switch safety sensors at the ends of the bath

- Latest generation programmable logic controller with Ethernet connection interface

- Control via PC in direct connection or via LAN network (remote control possible)

- High acquisition frequency

- Automatic detection of breakage (if load cells installed)

- Determination of elastic return with automatic calculation function

- Emergency stop on the front

- Power on indicator light

- Power switch-disconnector

- Management of sample incubation

- Taking Remote Control

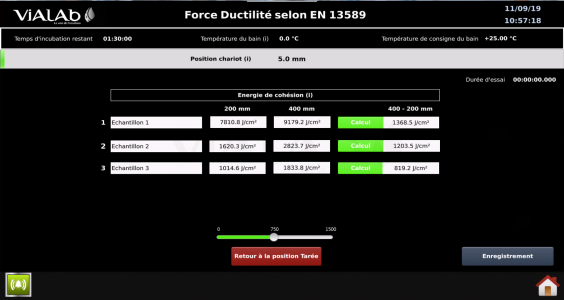

- 3 500 / 0.1 N load cells with respective signal conditioners

- Automatic recording of raw test data

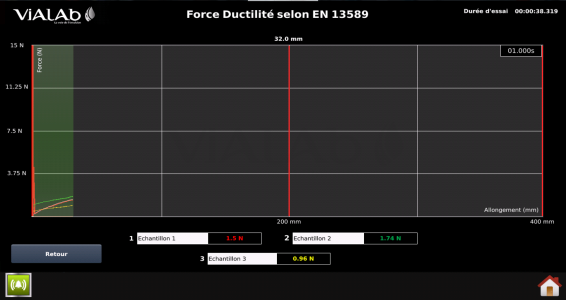

- Real time test curves

- Memorization of test curves

- Export of results in .csv file (Excel)

- Power supply: 230 VAC, 50Hz, 750W

Thermodynamics

- Circulating thermostat for temperature regulation from 5°C to 60°C at ± 0.5°C (chiller required for temperatures below or equal to ambient temperature down to -20°C depending on model)

- Control head with 2000 W heating coil

- Water level detection diver

- Pressure pump integrated in the control head

- Homogeneous distribution of the liquid flow in the bath thanks to the diffuser tube

Dimensions

- Dimensions (LxWxH; mm): 2360x580x310

- Weight: 140 kg

Accessories

- Windows laptop PC configured at the factory for controlling the ductilimeter

- Basic cooler for temperatures of + 5°C at room temperature (4 hours to reach 5°C at a temperature of 20°C)

- Performance cooler for low temperatures (down to -20°C) and for faster temperature drop

300 / 0.1 N load cells and signal conditioners

- Addition of a temperature display probe on the trolley

- 100% Made in France

- CE Certificate

F044.136.1550

Molds & Bases

BASE PLATE

(x3)

Specifications

- For the preparation of test molds

- Brushed aluminum

- Pressure screw

F025.136.1902

MOLDS | ELASTIC RECOVERY | EN 13398

(x3)

Specifications

- Brushed brass

- 4 parts

- 2 x Ø 10 mm brackets

- 2 x Spacers

F025.136.1901

MOLDS | ELASTIC RECOVERY | ASTM D113

(x3)

Specifications

- Brushed brass

- 4 parts

- 2 x Ø 10 mm brackets

- 2 x Spacers

F025.136.1905

MOLDS | FORCE DUCTILITY | EN 13589

(x3)

Specifications

- Brushed brass

- 4 parts

- 2 x Ø 6.50 mm brackets

- 2 x Spacers

F025.136.1904

Accessories & Options

COOLING SYSTEM | PERFORMANCE

Specifications

- In-line cooler to be connected to a circulation thermostat for ductility bath

- For efficient temperature regulation

- Allows to reach down to -20°C and to increase the regulation capacity under 15 C (150W at 0°C),

- Power supply: 230 VAC, 50 Hz, 200W

- Dimensions (DxHxW; mm): 250x360x190

- Weight: 16 kg

F077.125.1580

COOLING SYSTEM | BASIC

Specifications

- In-line cooler to be connected to a circulation thermostat for ductility bath

- Ideal for regulating the bath temperature around the ambient temperature

- Allows to reach 5 ° C in 4 hours at 20 ° C

- Power supply: 230 VAC, 50 Hz, 200W

- Dimensions (DxHxW; mm): 448x330x440

- Weight: 18.6 kg

F044.125.0300

ORDINATEUR PC PORTABLE

Specifications

- Laptop

- Operating system: Windows 10

- Hard Disk: 1000 GB

- Memory Capacity: 8 GB

- Intel 1.1 GHz processor

- 15.6 ″ screen

- (Configuration subject to change – non-contractual)

F044.199.1000

Français

Français Español

Español