PRODUCTS

VISCOSITY BATH | 20 L | 3 SAMPLES

Specifications

- TV2000 MKII 230 V 50/60 Hz

- Temperature range: T ambient at 230°C.

- Temperature stability is ± 0.01 K

- Ultra precise temperature control

- Determination of kinematic viscosity

- Thermometer calibration

- Density and reaction rate measurement

- Bath volume 20 liters

- Three openings to hold samples.

- Integrated cooling coil for working below room temperature

- Accuracy 0.01°C

- Stainless steel construction with 25mm thick rock wool insulation

- Ensures exceptionally stable temperatures which are further improved by an ingenious agitation mechanism.

- The bath is equipped with adjustable feet

- The bath cover has a number of round holes of Ø 51 mm with covers

F075.137.0771

VACUUM SYSTEM | TVS

Specifications

- TVS 230 V digital vacuum system controller

- Precise preselected negative pressure – 300 mm Hg for ASTM D2171.

- Range of 20 .. 320 mm Hg [30 .. 430 mBar].

- The pump maintains the vacuum within 0.5 mm Hg of its set point.

- The internal pump provides a vacuum which can be set on the front panel.

- The set point is kept in memory and automatically defined after power-up.

- The internal tire regulates the vacuum around this set point.

- In the event of a leak or a change in volume, the electronic feedback system will maintain the preset vacuum.

- Extremely small footprint compared to some other vacuum systems

F075.137.0940

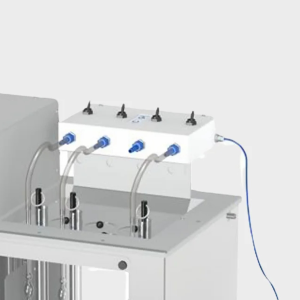

FOUR POSITION MANIFOLD

Specifications

- Vacuum collector | Manifold

- Adapt to the connection of viscosity baths and vacuum controller

- TV2000 MKII

- TVS 230 V

- Silicone vacuum tube to be ordered separately

F075.137.0941

Français

Français Español

Español