Products

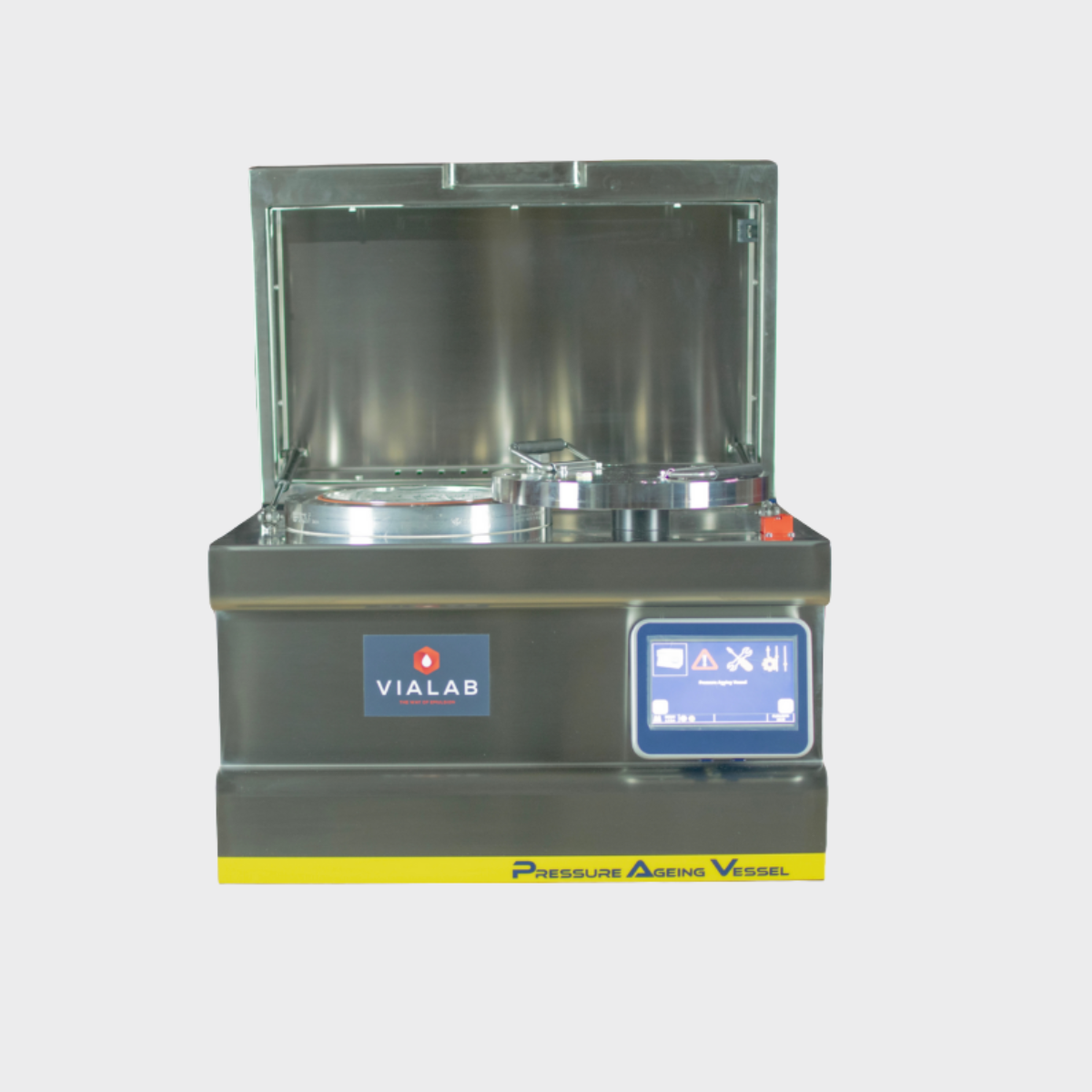

PRESSURE AGING VESSEL | PAV

Specifications

According to AASHTO R-28, ASTM D6521 and EN 14769 and CE and ASME safety standards.

Security

- Pressure release valve

- Temperature limiter

Ease of use

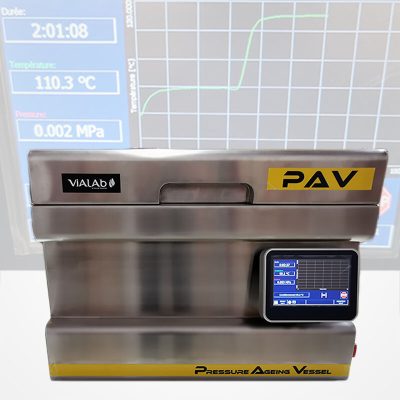

- Integrated 7 ″ digital touch screen controller,

- 4 test options pre-programmed at 85.0, 90.0, 100.0 and 110.0 ° C for 20 or 65h,

- Semi-automatic mode from 60 to 120 ° C and 20 to 65h.

- Search mode (Manual) for testing Temperatures (ambient at 130 ° C) and non-standardized durations (1 to 99h).

Controller

- Digital touch screen control (accuracy +/- 0.03 MPa)

- Temperature measurement by multiple platinum probes

- Pressure measurement by transducer

- Duration measurement

- Data storage on USB key (temperature, pressure, duration)

Pressure management

- Pressure management at 2.1 +/- 0.03 MPa

Temperature management

- Programmable ambient temperature at 130°C (display at +/- 0.1°C)

- Temperature uniformity at ± 0.5°C

- Programmable preheating function up to 60°C

Air supply

- By standard industrial compressed air bottles (not supplied)

- Provide a pressure regulator (F025.138.9231)

Delivered with

- Rack 10 containers

- 10 containers Ø 140 × 9.5 mm

F025.138.9230

VACCUM OVEN | PAV

Specifications

For the application of AASHTO R28, ASTM D6521 standards for accelerated aging under pressure of bituminous binders.

The aging process of PAV bituminous binders leads to the formation of air bubbles in the exposed binders, which must be removed at the end of incubation.

The degassing enclosure was designed to carry out this step at temperatures between ambient and 200°C, under a vacuum of 15 ± 1 kPa as defined in the standard.

Enclosure consisting of the following

- Heating chamber (up to 200°C) in stainless steel, under sealed vacuum

- Hinged cover

- Temperature control by platinum probe

- Automatic air inlet valve at the end of the cycle

- Overheating safety

- 7″ Digital touch screen with real-time reading of temperature and pressure parameters

Operating modes

- Automatic: 170 +/- 4°C for 30 minutes,

- Semi-automatic: temp. from ambient to 200°C, 30 minutes cycle,

- Manual: temp. from ambient to 200°C, cycle from 1 to 99 minutes.

- Cycle pressure: 15 ± 1 kPa (display at 0.1 kPa)

F025.138.9240

Accessories & Options

PRESSURE REGULATOR | PAV

Specifications

- To regulate the pressure at the outlet of compressed air bottles

F025.138.9231

SUPPORT RACK | 10 CONTAINERS | PAV

Specifications

- Support rack for 10 samples (containers) Ø 140 x 9.5 mm

F025.138.9232

Français

Français Español

Español