Products

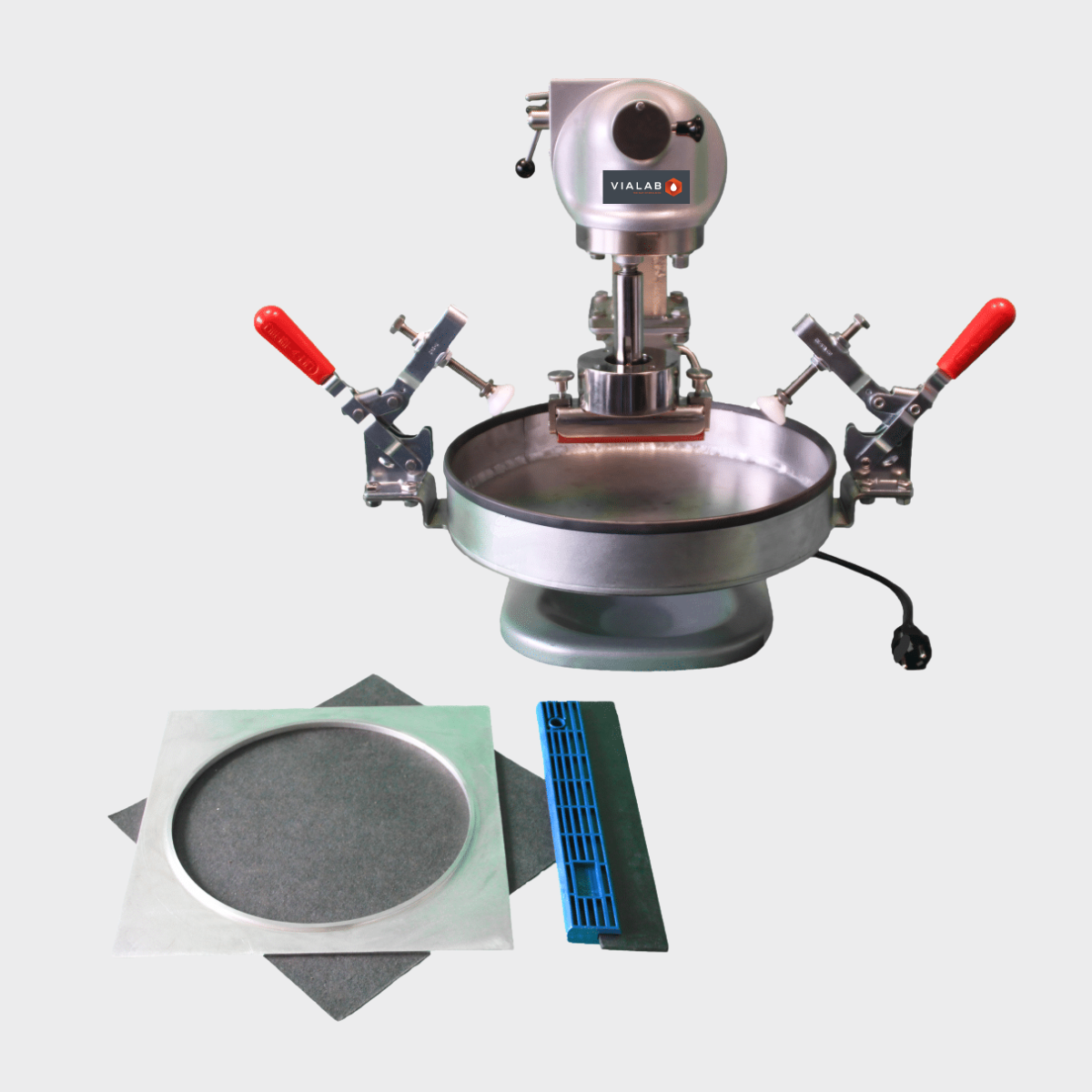

Wet Track Abrasion Tester

| Allowing abrasion testing in accordance with ASTM D3910 and ISSA TB100 for cold-cast bituminous materials.

Set of

Set of test accessories

|

F044.154.0010

Spun Aluminium pan

F044.154.0012

WTAT Mold in stainless steel

F044.154.0013

Set of accessories

- Smooth surface bowl in stainless steel

- Roofing felt

- Dowel

- Squeegee

Parker Hoses Shore A hardness rubber reinforced with a double cord surface

- ID Ø 19 ±2mm

- Thick 4.75…5.75 mm

- Length 127 ±3 mm

F044.154.0011