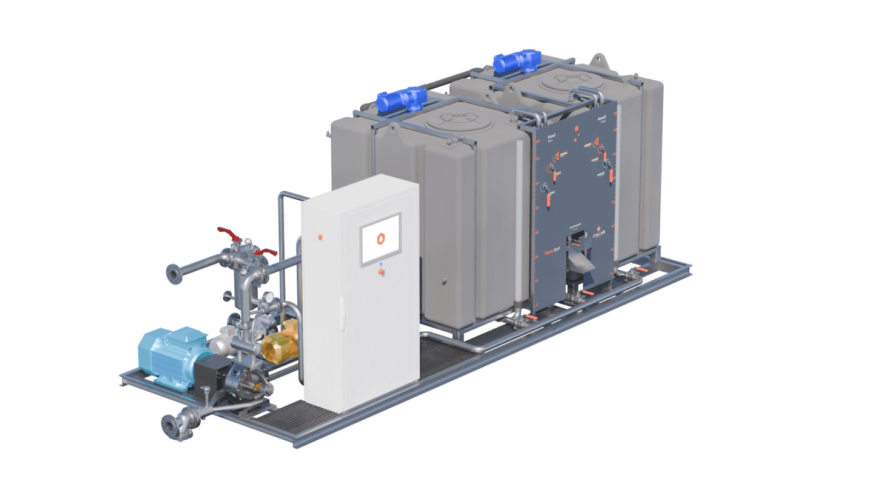

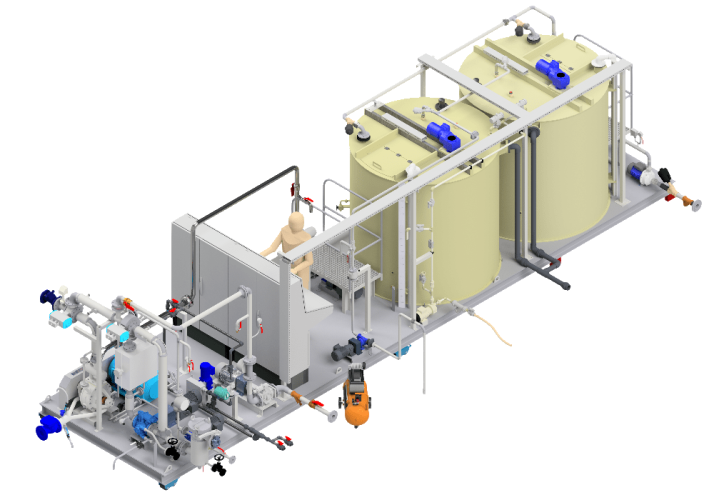

Bitumen Emulsion Production Plant

EMULSION UNIT TAILORED TO YOUR NEEDS :

Production capacity : 3, 5, 15, 30 T/h

Process : Continuous or Discontinuous

Piloting : Manual, Assisted or Automatic

Bitumen : Pure, Fluxed, PMB, Light colored binders, Addition of latex

Componants and number of lines : Binder, Soap solution, Emulsifier(s), Acid, Fluxing agent, Latex, Dope

Heating : Electric or Heating fluid

Implanting : Stationary, Modular or Mobile

Soap solution production : Batch, Flow or Hybrid

Hot water : Instant production, In-tank or Cogeneration

Emulsion cooling : with Water or Aerothermal

FAQ : frEquently asked questions

Which unit do I need to produce my emulsion ?

The configuration of the production plant depends on the emulsion(s) to be produced. In order to figure out the type of emulsion production unit needed, it is important to figure out the targeted applications, the ingredients used as well as the production volumes. Then, our business managers are there to into the details.

What is the lifetime of an emulsion production plant ?

Our robust plants last at least 20 years. In order to maximize the lifetime and the cost-effectiveness of the production units, regular maintenance as well as quality training of the operators is necessary.

Other questions ?

Ask them in the “Ask for Quotation” section down below or via email at contact@vialab.fr. Our experts will answer shortly.