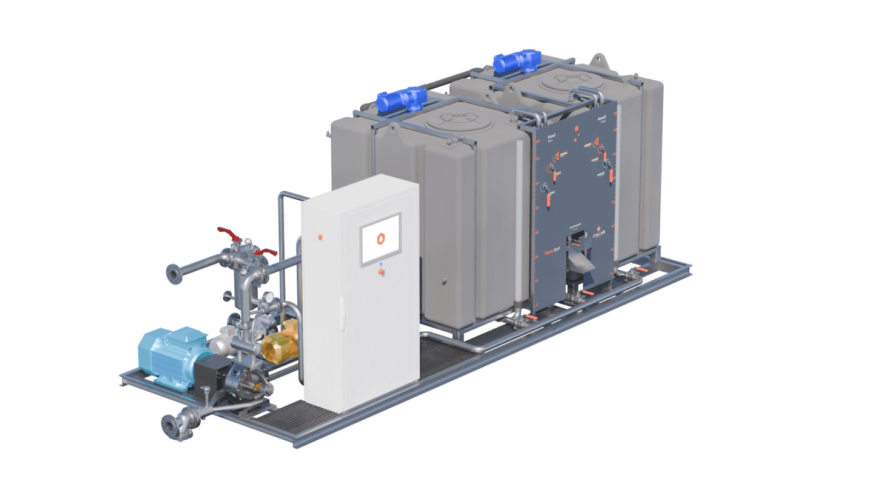

Hevo Start – Emulsion plant 15 T/h

A STANDARD UNIT THAT IS COMPACT AND VERSATILE

Compact, adaptable and intuitive, this unit is designed to meet a wide range of needs, with ergonomics and product quality as priorities.

With Hevo Start, reach your objectives while contributing to the decarbonation of the road sector.

Capacity : 15 T/h

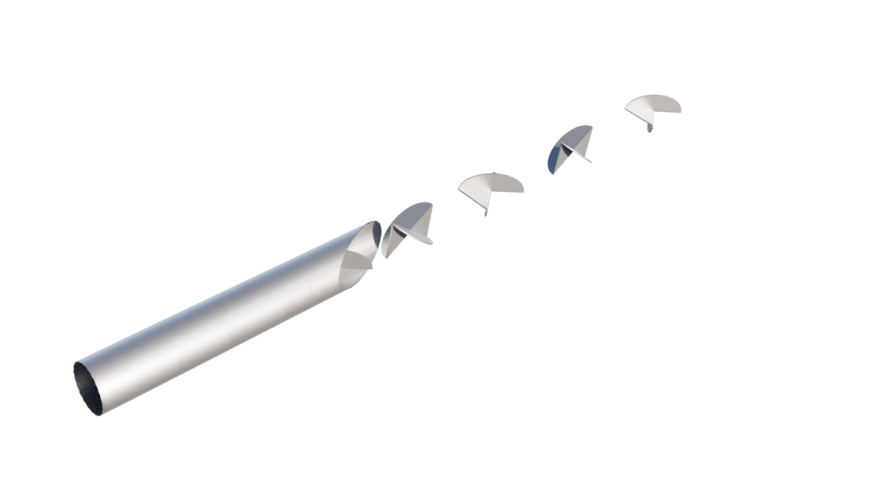

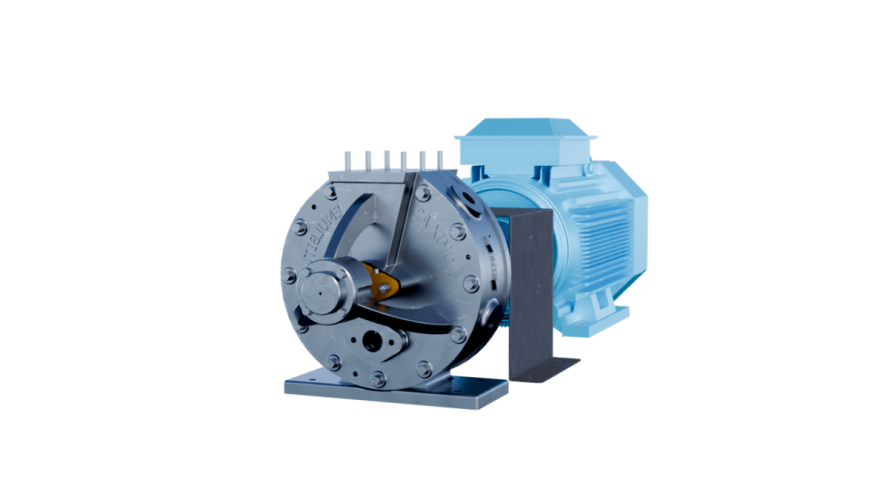

Homogenizer : ATOMIX® A2

Soap solution tanks : 2 x 3000 L

Piloting : Automatic with manual valves

Heating : Electric

Structure : Single frame

|

PRODUCTIVITY

Produce emulsions continuously thanks to the easier managment of the aqueous phase productions. Hevo Start comes with two 3000 L tanks in addition to fully automatic stirring and injections for the hot water, the activator as well as the emulsifier.

The variable pumps for the binder and the aqueous phase bring the liquids to the ATOMIX® homogenizer, which is a widely known technology and the center piece of all the emulsion plants from VIALAB. All these elements are combined together in order to provide you with thin emulsions and high quality productions.

|

CONTROL

Select your ingredients, choose your formula, and start producing. The software calculates all the amounts of ingredients and then guides the operator step-by-step through the actions to be carried out.

Hevo Start saves the output reports to allow you to monitor your productions and manage your material consumptions.

Regarding maintenance, the software is equipped with self-control functions that provide the necessary information to take care of your plant. On top of that, all the software functions of Hevo Start have user-dependent accessibility, which increases user confort and safety.

|

VERSATILE

The Fluxing option increases the versatility of Hevo Start by giving access to highly fluxed emulsions including impregnation and storable cold mix emulsions.

Doing so, the abilities of the machines are multiplied and two productions are combined : Emulsions and Fluxed/Fluidized bitumen (Cutback).

To control your productions completely, the Measuring option adds the evaluation and the storage of data regarding pH, temperatures, continuous tank levels, as well as all the software functions to compute and analyze this data through the onboard intelligence.